Oil in water monitoring prevents contamination of cooling towers, heat exchangers and steam condensate.

Many industries require cooling water to transfer heat from the process out of the system. The cooling water must be then be cooled down and discharged before being replaced with fresh water.

Oil from heat exchanger leakages in cooling water causes at best the fouling of the packing leading to inefficient cooling of the water or at worse a potential shutdown of the plant. Oil and grease in the discharge water can also mean a hefty fine from the Environment Agency (EA).

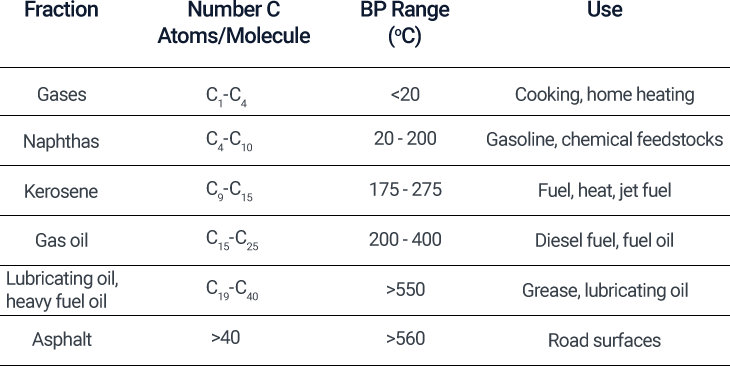

Measuring ‘oil’ in water is a challenge. Whilst regulators may define a consent in terms of ‘oil’ permitted to be discharged, that oil can be made up of many different hydrocarbons, some saturated (aliphatic hydrocarbons) and some unsaturated (aromatic hydrocarbons).

Different measurement methods are more or less sensitive to different types of hydrocarbons. Added to that complication is that the hydrocarbons are in a media (water), often not dissolved and spread evenly throughout it. Some hydrocarbons will float on the top of the water, some will stick to other particles or a sample container, and some will stay as insoluble droplets floating in the water.

Why use fluorescence as a method for online monitoring of cooling water?

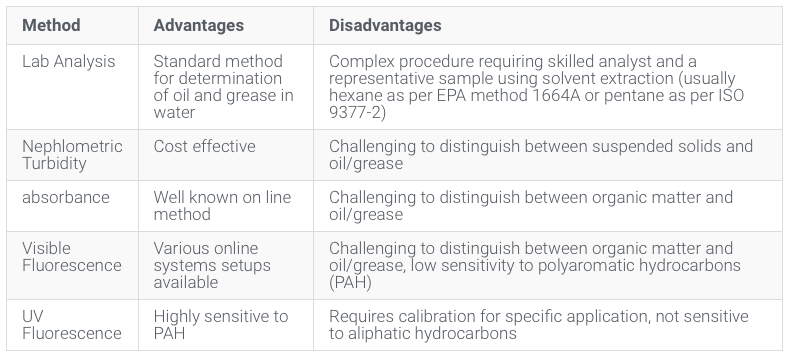

There is no perfect solution to oil in water measurement. Without the ability to carry out an extraction, continuous monitoring such as that required in the cooling water of a power plant is even more challenging. But UV fluorescence methods have some distinct advantages over alternative oil in water monitoring techniques.

Sensitivity

UV Florescence methods are highly sensitive to aromatic hydrocarbons such as that found in refined oils used as lubricants or in power generators. This enables detection of leakages into the cooling water down at the parts per million (ppm) level.

Detects both dissolved and insoluble hydrocarbons

With UV fluorescence, it doesn’t matter what form the aromatic hydrocarbon is in. Dissolved or not, the hydrocarbon will fluoresce leading to its detection.

Specificity

Using the flexibility of different excitation and emission filters affords us, we can be highly selective as to the type of hydrocarbon that is to be detected.

Reduced turbidity effects

Suspended solids don’t tend to fluoresce, so are handily excluded from any UV fluorescence measurement.

Advantages and Disadvantages of different oil in water methods.

Integrated Oil in Water Monitors

TD 4100XD

Designed for applications such as crude/produced oil measurement, wastewater discharge and intake protection.

Knowledgeable, experienced staff.

Need some advice or support? We’re here to help.

If you need a call back about how Process Measurement and Analysis can help you or have any questions at all please feel free to contact us at [email protected]. A member of our experienced team will contact you directly.