Online oil in water monitoring in once-through Cooling Water systems

Power plants and paper mills use service water loops and mill water loops respectively for the cooling of lubricating, hydraulic, turbine and transformer oil. These cooling systems feature large, recirculating volumes of water which are treated with biocides, dispersants, and corrosion inhibitors.

By comparison, refineries often use once-through cooling water systems. The cooling water is taken from lakes, rivers, or the ocean and circulated once through the plant to cool processes. Large volumes of water are used to keep the return water temperature low enough to prevent adverse effects on the environment.

Falling levels in lube oil tanks are one indication that oil is being lost in the process. Visible oil drips on the ground can also indicate an oil leak. However, because of the high water volumes used in once-through cooling systems, it can be difficult to see oily discharge sheens in the returned water.

Some leaks can be intermittent as a process heats and cools, or as water or oil pressure changes. Occasional sample analysis of the cooling water may not catch the intermittent leaks or may not be frequent enough to prevent substantial oil loss. An online monitor can quickly reveal small intermittent leaks and indicate the potential for significant oil cooler tube failure before it occurs.

The solution to oil in water monitoring in once-through cooling systems

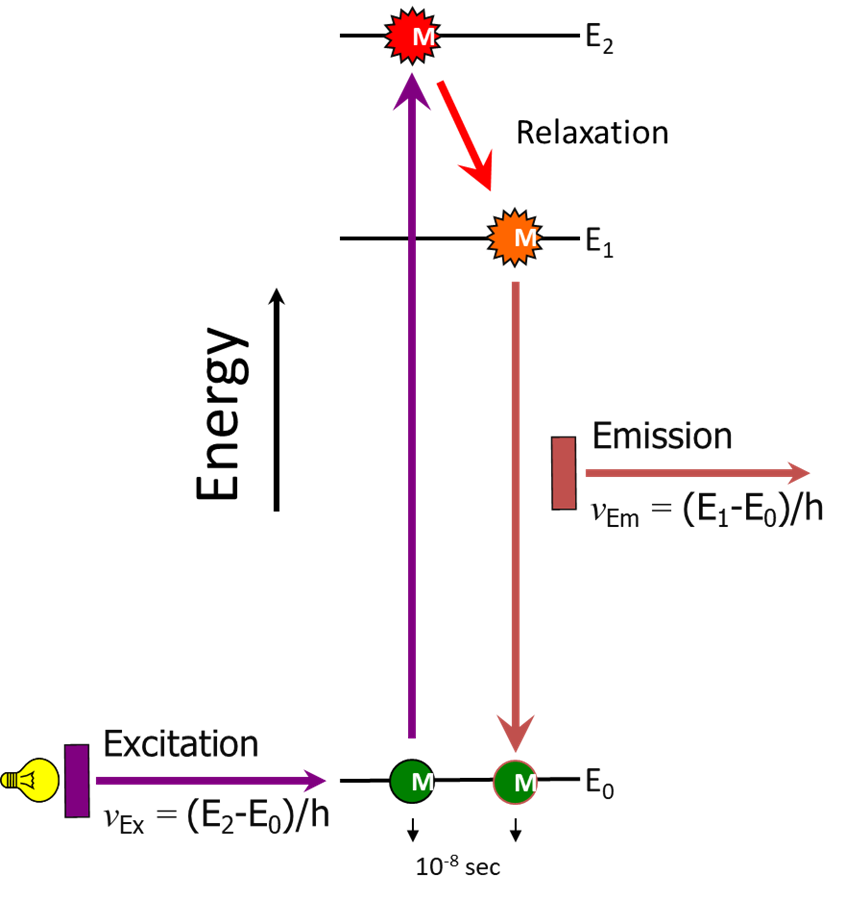

Fluorescence-based oil in water monitors from Turner Designs Hydrocarbon Instruments has been used extensively in industrial water processes for more than 20 years. These low maintenance fluorescence monitors have no significant measurement disturbance from water turbidity or naturally occurring organics in the water.

Oil leaks can damage critical equipment or require an extended shut down of the process being monitored. The TD-120 Oil in Water Monitor protects against this loss of equipment and productivity. The TD-120 detects most petroleum-based fuels and lubricating, hydraulic, transformer, and turbine oils at less than 1 ppm. With multiple measurements per second, the response time of the TD-120 is fast enough for process control. The included, unique smart sensor is easily calibrated and incorporates a simple factory test to confirm your TD-120 is performing per factory specifications at any time. The TD-120 requires no sample preparation, reagents, or instrument air supply. With a long-life LED and optical sensor(s), the TD-120 is expected to operate for more than 5 years with no significant maintenance or spare parts costs. These features make the TD-120 Oil in Water Monitor ideal for quick, reliable detection of oil in raw water intakes and leaks in once-through cooling water.

Find out more about the TD120

Find out moreKnowledgeable, experienced staff.

Need some advice or support? We’re here to help.

If you need a call back about how Process Measurement and Analysis can help you or have any questions at all please feel free to contact us at [email protected]. A member of our experienced team will contact you directly.