Preventing flow accelerated corrosion in combined cycle heat recovery steam generators using online turbidity measurement for iron monitoring

Flow accelerated corrosion has been demonstrated as one of the leading causes of corrosion in heat recovery steam generators. However, monitoring of the total iron in the boiler feedwater can be challenging with a lean operation given the low levels of total iron that are to be expected when flow accelerated corrosion is under control.

Low level ppb analysis of iron can be difficult. Some chemistries used by online analysers do not have a low enough limit of detection required for the application. The best colorimetric chemistry is clearly ferrozine, with its low level of detection and high thioglycolic acid content which is able to dissolve and reduce some iron oxides into a form that can react with the ferrozine to produce the characteristic purple colour. Hematite has been shown to be more challenging to break down even with thioglycolic acid, thus a digestion step is often utilised to be able to ensure all the particulate iron is measured. This rules out most online iron analysers.

An alternative approach for monitoring corrosion in real time is to use nephelometric turbidity measurement.

Corrosion of steel components in power generation leads to a number of different iron forms in the process water, principally magnetite, hematite and dissolved iron. Given that each site will have different ratios of these components in their boiler feedwater, any turbidity analyser being used for online real time corrosion monitoring must have a site-specific calibration generated. Of course, it must be remembered that dissolved iron will not scatter any light and a turbidity measurement will only measure the particulate iron content.

In conclusion, a suitable online iron analyser using ferrozine chemistry alongside a precise low-level turbidity analyser will enable an operator to fully understand the levels of iron in the boiler feedwater, whatever form that it may be present in.

Products for this application

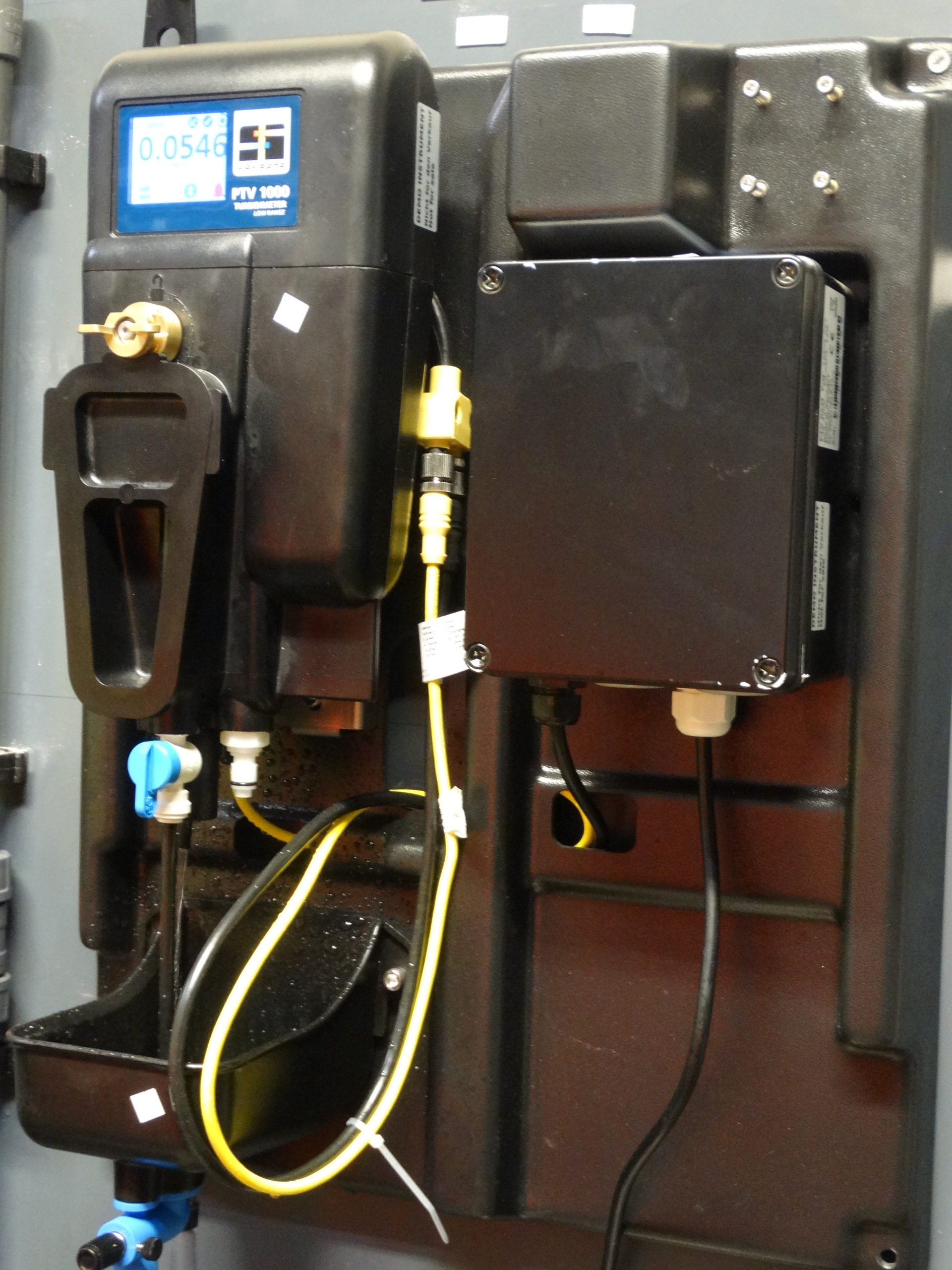

PTV1000 turbidity analyser

An online turbidity analyser for total iron monitoring in boiler feedwater applications for the prevention of flow accelerated corrosion.

Knowledgeable, experienced staff.

Need some advice or support? We’re here to help.

If you need a call back about how Process Measurement and Analysis can help you or have any questions at all please feel free to contact us at [email protected]. A member of our experienced team will contact you directly.